- Perfect Processing Quality

Design based on several decades of experience and know-how in dedicated industrial X-ray film processor design and construction.

State-of-the-art technology to guarantee high-quality x-ray film processing. - Minimum Processing Costs

Precise control of replenishment ensures accurate chemistry consumption.

Minimum volume of water (as little as 13 l/m2 with our ECO processors) used during processing, creating a low ecological impact.

Low consumption of electricity due to the infrared drying system and other design elements, such as the automatic standby switch. - Low Heat Emission

All Waygate Technologies processors feature infrared drying, guaranteeing not only uniform drying of x-ray films, but also reduced energy consumption – helping to keep darkroom temperatures down.

Easier to maintain comfortable working temperatures in the darkroom. - Adjustable Film Receiving Tray

Easily-adjustable film receiving tray for all Waygate Technologies processors to suit the kind of film size being processed – including sheet film, welding formats or roll film.

Processed films collected in the tray in the order of the film being inserted.

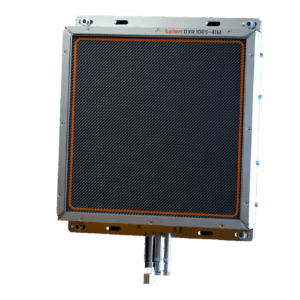

Processors Industrial X-Ray Film

Depending on the place, situation and application, processing of the industrial X-rays films are carried out manually or automatically. Complete solutions are available to choose the best way of processing your films in combination with STRUCTURIX chemicals and equipment, all perfectly suited to one another. Waygate Technologies provides a complete range of STRUCTURIX processors, from a versatile tabletop model to a highly sophisticated one and from low to high capacity – all designed to ensure high-quality results.