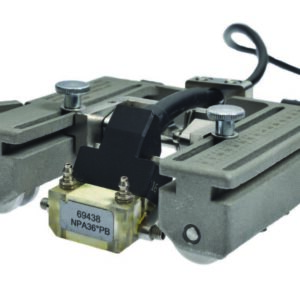

- Krautkrämer USIP|xs CV – ESSENTIAL & PERFORMANCE LINE

- Krautkrämer USIP|xs CV: Key Highlights

Ease of Use

The plug-and-play instrument applies the latest usability standards and is equipped with a vast array of integrated diagnostic features. This allows a quick start-up and operation without excessive training of staff and learning efforts. The integrated box design of the USIP|xs CV makes the instrument extremely easy to maintain in comparison to slot card type electronics.

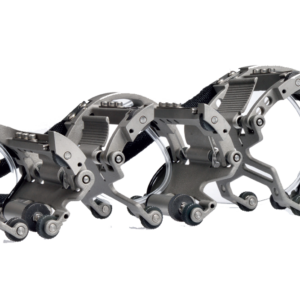

Industry-leading automation and integration capabilities allow for even the most complex systems to be built with less effort. Multiple interface standards – including field bus – make USIP|xs CV one of the best equipped instruments for effective integration into automated systems.

As one of the largest platforms of conventional ultrasonic instruments, the new Krautkrämer instrument offers UT performance and channel count perfectly fitted to individual inspection needs. In contrast to a “one-size-fits-all” solution, the USIP|xs CV creates synergies concerning technical infrastructure, instrument cost, and training and integration know-how, reducing the overall complexity of setting up and maintaining inspection systems.