- WELD STANDARDS & DICONDE COMPLIANT

Compliant to ISO 17636-2 Class A and B, ASME, ASTM and EN weld inspection standard. - HIGH RESOLUTION

Extremely wide latitude eliminating the need for multiple gain settings when exposing over a wide range of thicknesses. - HIGH THROUGHPUT

Designed for extremely high throughput: 90 plates/hr at 70 microns or 28 plates/hr at 35 microns for a 10 x 40 cm (4.5 x 17”) plate.

Allows multiple imaging plates to be scanned simultaneously reaching 84 plates/hour at 35 microns for 10 x 40 cm (4.5 x 17”) plate at 3 image plates entry. - FLEXIBLE

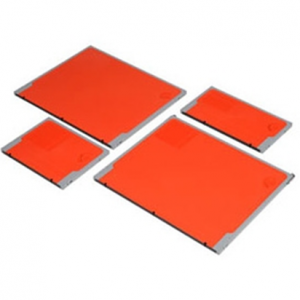

Ability to scan any shape or size of imaging plate from 20 to 1500 mm (0.75 to 60”) in length. - EXTENDED PLATE LIFE

Each imaging plate has the ability to return to a flat state after being constantly bent around pipes for the inspection of welds.

Improves productivity by allowing the imaging plates to be easily extracted and reinserted into cassettes. - INTUITIVE

Simplifies inspection workflow. Ability to automatically crop the images by detecting the physical edges of each individual plate when they are processed - AMBIENT OPERATION

Can be used in ambient light conditions with suitable handling as the light cover protects the plates from light exposure during the scan cycle.

Cover can be removed for work in darkrooms if required.[/vc_column_text][/vc_column][/vc_row]

CRxVision

CRxVision is the high resolution weld inspection and all-purpose computed radiography scanner from Waygate Technologies. Packed with innovative features to increase throughput, extend plate life and provide excellent image quality, the CRxVision is designed specifically for the inspection of welds. The scanner is developed to cover the stringent ISO 17636-2 Class A and B requirements, as well as ASTM, ASME and EN weld standards. Because of its versatility, it can also be used for many other applications across the NDT industry.

Applications

Even though the CRxVision was designed for the inspection of welds, it also has the ability to cover a wide range of industrial radiography applications, from Oil & Gas to Aerospace, and from Power Generation to General NDT.

- Weld inspection

- Erosion/Corrosion inspection (CUI, FAC, etc.)

- Castings (In-process and final)

- Valve positioning

- Concrete and Structure inspection

- Government (Arsenals, National Laboratories, Proving Grounds)

- Military (in-service aircraft, ships, etc.)