– Speed: Scanning, data analysis, and reporting in one quick workflow

– Highest resolution on the market offering easy to understand C-scan imaging

– High-probability of corrosion detection with defects down to 1 mm (0.04 in) identified

– Simple in-service deployment: No couplant and minimal surface preparation required

– Easy to operate with minimum training required

– Flexible heads fit a full range of pipe and vessel sizes

– Full data recording with adjustable reporting threshold feature

General

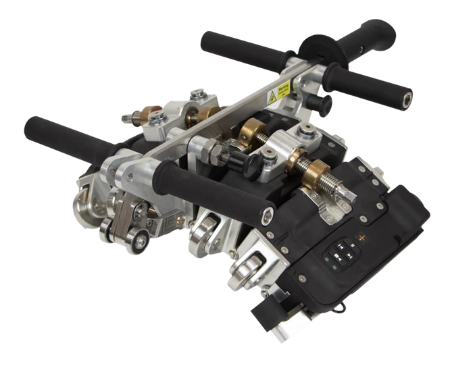

Technology: Magnetic Flux Leakage / Hall Effect Sensors

Method of propulsion: Hand Push Speed up to 1 m/sec (40 in/sec)

Coating thickness: Up to 6 mm (0.2 in) non magnetic material

OD range (real value): PS-HD-MFL-127XFLAT: 127 mm to flat (5.0 in to Flat)

PS-HD-MFL-73X127: 73 mm to 127 mm (2.875 in to 5 in)

PS-HD-MFL-48X63: 48 mm to 64 mm (1.9 in to 2.5 in)

Recommended wall thickness: PS-HD-MFL-127XFLAT: Up to 12.7 mm (0.5 in)

PS-HD-MFL-73X127: Up to 8.56 mm (0.337 in)

PS-HD-MFL-48X63: Up to 6.05 mm (0.238 in)

Number of channels: PS-HD-MFL-127XFLAT: 27

PS-HD-MFL-73X127: 17

PS-HD-MFL-48X63: 9

Channel spacing: 7 mm (0.27 in)

Smallest detectable defect: Detection from Ø >2 mm and 10% wall loss

Maximum surface temperature: 60°C (140°F)

Connecting cable: 5 meter (15 feet) standard length

Weight: PS-HD-MFL-127XFLAT: 30 lbs (13.4 Kg)

PS-HD-MFL-73X127: 20.5 lbs (9.3 Kg)

PS-HD-MFL-48X63: 12 lbs (5.5 kg)

Transit case: Meets IATA requirements for transporting magnetizable material

Compatible Instruments: Swift-M, Reddy-32M