– Ultra-efficient workflow and acquisition speed for rapid inspection and sentencing

– Dedicated pipe girth weld interface powered by the UltraVision® software engine with long history and global support

– Mission-critical reliability trusted by leading industries including oil & gas, nuclear power, defense, and aerospace

– Support for multiple techniques—Zonal PAUT, TOFD, PWI, TFM/PCI for high-speed assessments

– Real-time results and rule-based assisted analysis for streamlined decision-making

SYSTEM

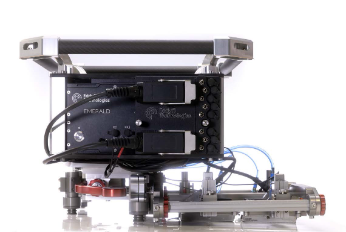

Instrument Mounted Specifications

Dimensions (w × d × h)

Configured for Ø12”: 397 x 696 x x 481mm (15.6 x 27.4 x x 18.9in)

Configured for Ø72”: 397 x 746 x 342mm (15.6 x 29.4 x 13.5in)

Dimensions (w × d × h)

Configured for Ø12” – 224mm x 596mm x 308mm (8.8in x 23.5in x 12.1in)

Configured for Ø72” – 224mm x 645mm x 233mm (8.8in x 25.4in x 9.2in)

Weight

7.5kg (16.5lb)scanner only

Weld band widths

Band cross-section geometry Standard idler wheel assemblies (BAS002) are compatible with typical CRC Evans or RMS Welding Systems bands

Minimum width 80 mm (3.15 in)

Maximum width 127 mm (5 in)

Instrument De-Mounted Specifications

Weld band diameters / pipe diameter ranges

Minimum OD

Standard configuration 203 mm (8in)

With drop-plate adapter 102 mm (4in)

Maximum scanning speed

177mm/sec (6.971in/sec)

Scanner power requirements 100-240 VAC, 50/60 Hz, 3.5A (Optional Battery)

Maximum umbilical length

60m (200ft)

Required radial clearance above band OD

On 10in OD band 232mm (9.1 in)

On 74in OD band 218mm (8.6 in)